Characteristics

- Provides excellent soft, fluffy,smooth, and elastic hand feel;

- Has good antistatic property and minimalcolor change;

- Acid-resistant; not resistant to hard water and alkali;

- Especially suitable for ultra-soft finishing ofacrylic fibersand their blended fabrics.

Dissolution Method

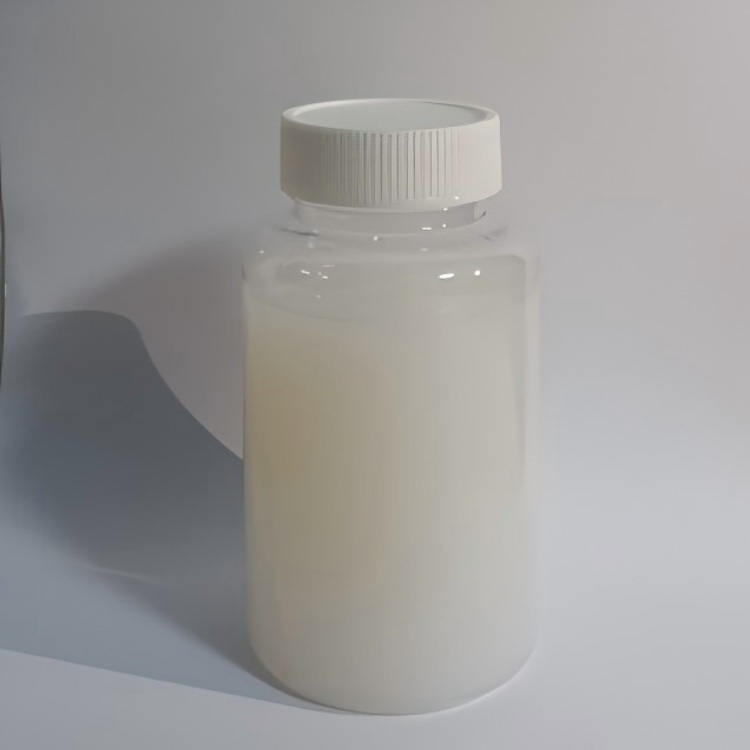

1) Emulsion Preparation

Cationic Softener Flake RF: 100kg

Deionized water or soft water: 900-1500kg

The specific dilution concentration can be selected by the customer according to equipment or actual production conditions. However, the dilution concentration should not be too high; otherwise, the dissolution time will be prolonged and the emulsion viscosity will increase, which is not conducive to use.

2) Operation Steps

First, add half of the required amount of cold water into the container, then slowly add Softener Flake into the cold water while stirring;Stir and soak for 10-20 minutes until the flakes are completely dispersed, then add the remaining half of the water;Heat while stirring. When the material temperature rises to 50-60℃, continue stirring and dissolving for about 1.5-2 hours until the flakes are basically completely dissolved;Stop heating, and continue stirring until the emulsion temperature drops below 40℃ and a uniform emulsion is formed. Then stop stirring to avoid skin formation on the emulsion surface. After the emulsion is prepared, filter it for later use.

Note: During the entire stirring process, the rotation speed does not need to be too high, and 100-200 rpm is appropriate. If the emulsion cools too quickly, a skin may form on the surface of the emulsion.The skinned material can be scooped back into the dissolving bucket for re-dissolution, which does not affect the application performance.

Application Method

The emulsified and diluted softener can be used directly. Fabrics treated with Softener Flake RF should be dried as soon as possible.

① Dipping Process

Softener emulsion: 2~ 10% (o.w.f, On Weight of Fabric)

pH Value: 5.5-6

Liquor ratio: 1:8-10

Temperature × Time: 30~40℃ × 15-25 minutes

② Padding Process

Softener emulsion: 10~40g/L

pH Value: 5.5-6

Pad liquor pickup: 60-80%

③ Softening Example for Acrylic Knitted Fabric (Yarn)

Softening treatment during the dyeing cooling stage: After dyeing, cool down to 60℃ at a rate of 1-2℃/min, add 2-5% of 978 softener emulsion (10%), continue cooling to 40℃, then perform centrifugal dehydration

and drying.

Softening in the cooled dye bath: Maintain the pH of the dye bath at 5.5-6.5, add 978 softener emulsion, treat for 20-30 minutes, then perform centrifugal dehydration and drying.

④ Stripping Process

Detergent MFB: 0.5-1.0 g/L

Formic acid: 1-3 ml/L

Temperature × Time: 98℃ × 30 minutes

Subsequent steps: Water washing → neutralization with sodium carbonate → water washing → drying.

Storage and Transportation

Transported as non-hazardous goods;

Packed in plastic bags, 25kg per bag;

Stored in a cool, dry, and well-ventilated warehouse; shelf life is 1 year.